Godswill Balers

If you need strong, high-quality industrial baler machines, we’ve partnered with Godswill to deliver exactly that. Our aim is simple: to provide you with the best waste management products available in the market.

Our lineup includes a variety of baler machines, such as channel balers, twin ram balers, closed door balers, and custom-built options. These machines are designed to make waste management easier and more efficient for you.

No matter the size or type of waste you’re dealing with, our baler machine is here to help. From industrial sites to commercial businesses, we have the perfect answer for you. With our baler machine, you can expect great performance and reliability, making sure your waste management processes work well.

Baling Solutions

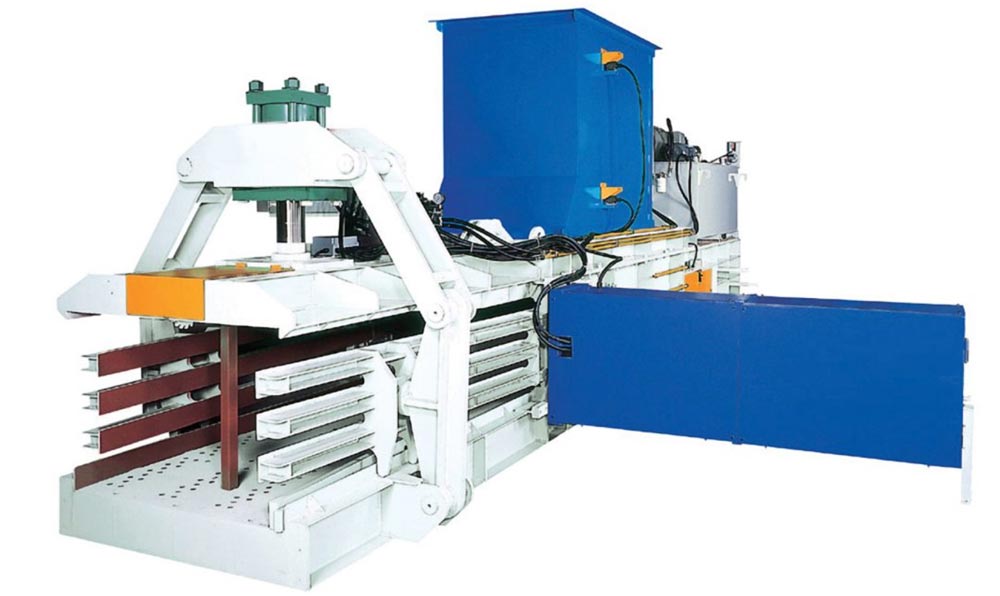

Channel Balers

Baling Solutions

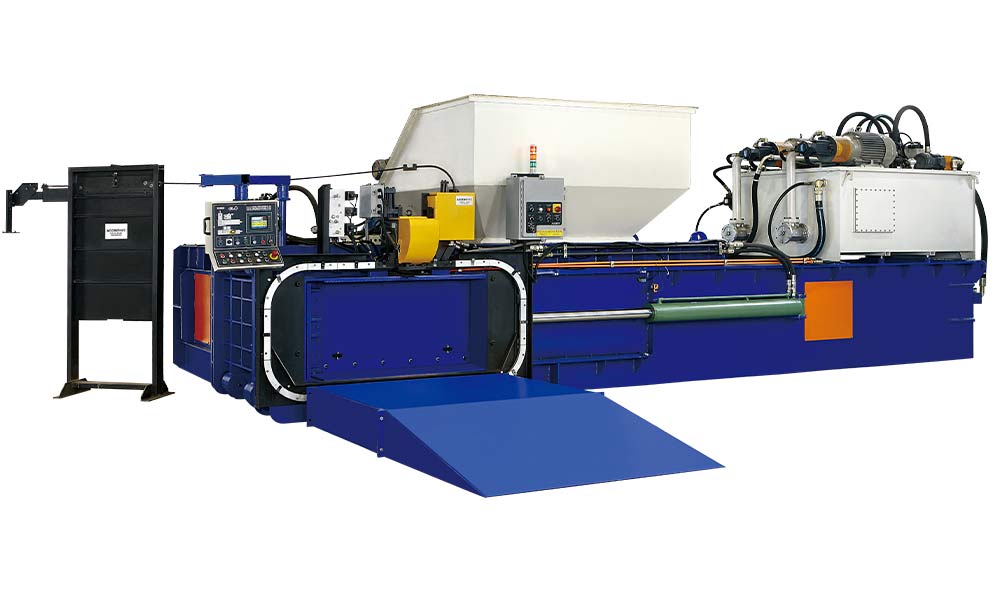

Twin Ram Balers

Twin ram baler machine is designed to compress materials into dense bales, offering productive waste management. With their ability to handle different types of materials, these balers assure optimal performance for your waste management. Click below to explore our range of twin ram balers and find the perfect resolution for your business.

Baling Solutions

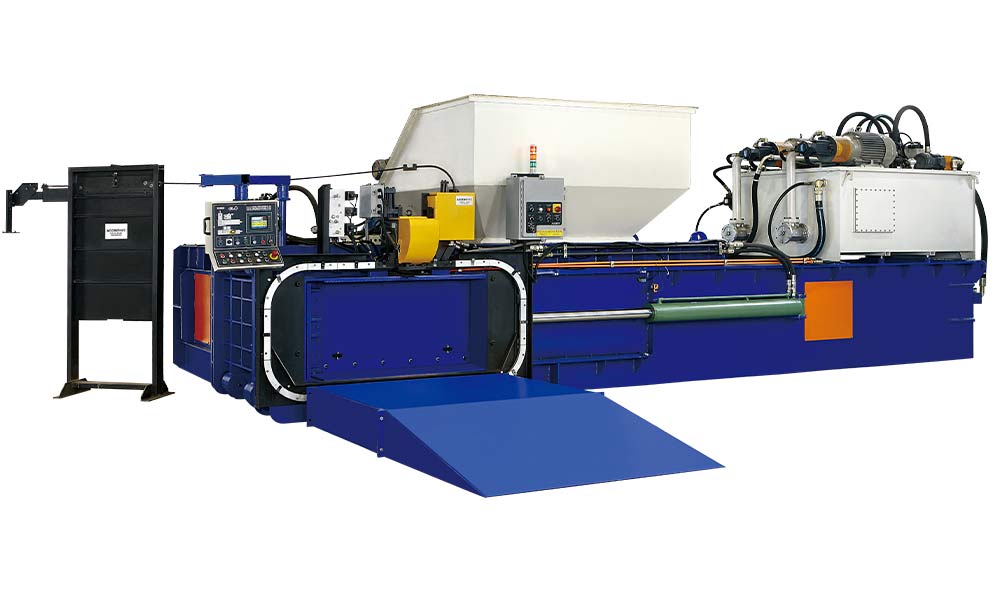

Closed Door Balers

Closed-door balers from Material Recovery Solutions provide better efficiency than vertical balers. They need less manual work and give higher output. Click below to learn more about our closed-door baler series and how they can make waste management easier for you.

Baling Solutions

Custom Build Balers

Explore our custom-designed baler machine, built to suit the specific industry. Our team knows how to find the best suited baler products to match your unique requirements, delivering optimal performance. Click below to discover more about our range of custom-built baler machine and find the perfect product for your business.

About Godswill

Since 1987, Godswill has been designing reliable baler machines of good quality, always striving to improve their work every day.

Using computers to design and create their machines since 1996 has helped them make better machines faster. Their employment of Computer-Aided Design (CAD), Computer-Aided Engineering (CAE), and Computer-Aided Manufacturing (CAM) systems has played an important role in this process. These computer systems facilitate efficient process and quality control, making sure each of their baler machine meets the highest standards.

Customer-centric approach

Godswill values their customers, aiming to provide the best service possible. They’ve set up a special system for after-sales service, making sure that they reach 100% customer satisfaction even after purchase.

Their vision extends to the future, where they seek continual improvement in their baler machines. They’re committed to growth and improvement of each design.

For greener future…

Godswill is dedicated to environmentally friendly machines. They’re constantly exploring ways to make their machines greener and more effective.

Innovation is at the heart of Godswill’s values, with a constant pursuit of new ideas and methods to further improve their machines. They uphold a standard of excellence, always aiming to be leaders in their field.

Contact us for baler machines

Take your waste management to a next level with our excellent baler machines from Godswill. Our channel baler is made to take care of different materials, making your baling tasks easier and more productive. When you need precision and strength, our twin ram baler is there for you, guaranteeing your bales are dense and reducing any delays.

Looking for a safer and more contained baling process? Our closed-door balers are the answer, keeping your employees safe while improving efficiency. They’re perfect for businesses that care about safety and getting the job done right.

At Material Recovery Solutions, we know that every business is unique. That’s why we offer custom-built balers designed to fit your specific needs. Our team will work closely with you to create a baler that fits perfectly into your operations, making them more productive.

Changing waste management

We understand how important it is for baler machine to work well and last long. That’s why we make sure to use the best materials and the latest methods when making our machines. This way, you can trust that each baler we provide will keep working great for a long time.

When you choose our baler machines, you’re not just getting equipment. You’re getting better operations and a greener future. Let us help you make waste management easier and more eco-friendly.

Ready to take your waste management to the next level? Reach out to Material Recovery Solutions today. Our team is here to talk about what you need and help you find the perfect baler for your business. Experience next level waste management with our outstanding baler technology.

Frequently Asked Questions

What's baler machine uses?

A baler machine is used to compact and bundle various materials such as cardboard, paper, plastics, and metals into manageable and transportable units called bales. These bales are easier to handle, store, and transport, making them ideal for recycling, waste management, and storage purposes. Baler machines are commonly employed in industries such as manufacturing, agriculture, retail, and waste management to streamline the handling and disposal of bulky materials.

How does baler machine work?

A baler machine works by compressing loose materials into compact bales using hydraulic pressure. The process typically involves feeding the materials into the baler’s hopper, where they are then compacted by a platen or ram. The ram applies force to the materials, compressing them into dense bales. Once the bale reaches the desired size, it is tied off or wrapped with wire, twine, or strapping to secure it for transportation or storage. Baler machines come in various types, including vertical, horizontal, and specialty balers, each designed for specific materials and applications.

How to operate a baler machine?

Operating a baler machine involves several steps to deliver safe operation. First, the operator must familiarise themselves with the machine’s controls, safety features, and operating procedures. Next, they load the materials into the baler’s hopper, making sure to follow any recommended guidelines for material placement and feeding. Once the materials are loaded, the operator activates the baler, typically by pressing a button or engaging a lever. They then monitor the compaction process to make sure that the materials are properly compressed and that the bale is formed correctly. Finally, once the bale is complete, the operator secures it with wire, twine, or strapping and removes it from the baler for storage or transportation.

Where can I buy baler machine?

You can buy baler machines from us at Material Recovery Solutions. We have a variety of balers that are perfect for different businesses.

Our baler machines are renowned for their durability and reliability, delivering consistent performance and optimal productivity in waste management operations. Whether you’re dealing with cardboard, plastic, paper, or other materials, our balers are up to the task.

When you choose to purchase a baler machine from us, you can expect exceptional customer service every step of the way. Our team of experts is dedicated to assisting you in selecting the right baler for your specific requirements. We’ll take the time to understand your needs and recommend the most suitable product to streamline your waste management processes

So, if you’re in the market for a baler machine, look no further than Material Recovery Solutions. Contact us today to speak with one of our knowledgeable representatives and take the first step toward streamlining your waste management operations with our high-quality baler machines.

Contact Us

Our knowledgeable staff is here to help you find the right solution for your business's specific needs. Call us now or use this form to contact us.

07 562 900 92

sales@materialrecoverysolutions.com.au

26 Blue Rock Drive

Luscombe, QLD 4207